Ladies and Gentlemen,

Dear HICON readers,

Old friends of EBNER and dear colleagues:

Our vision is to become the most innovative and competitive supplier of sustainable heat treatment solutions. We are constantly looking for ways to expand our product range and consolidate our market position. At the end of 2021, the two companies, each with its rich tradition, are moving forward hand in hand.

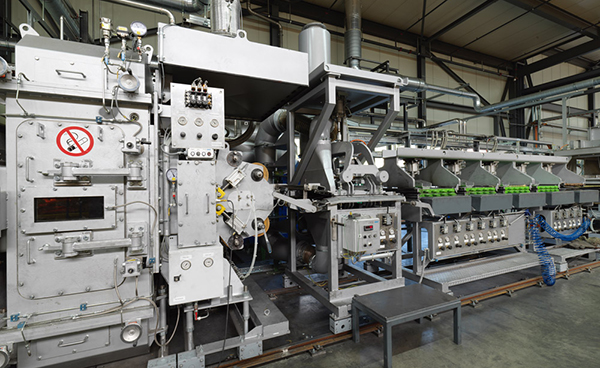

The American company Hazlett has become a member of the EBNER Group, adding more than a century of continuous casting technology and experience to our know-how.

Hazlett is a family-owned company with a history of 103 years.

Headquartered in Colchester, Vermont, USA, it has a total of 160 employees. Hazlett is currently investing in a test facility with extremely advanced technology. The test facility is prepared for the next generation of thin strip casting equipment.

With the development of this thin strip technology, the manufacture of aluminum strip with a thickness of less than 10 mm will become more economical and energy-efficient. Hazelett's perfected strip casting technology can process material thicknesses ranging from 15 to 38 mm and widths of up to 2 meters.

For the EBNER Group, the joining of Hazelett is another milestone on our road to providing complete solutions with advanced technology, while also enhancing EBNER's energy-saving and environmental protection technology, especially in the application of aluminum, copper and lead.

Gautschi has been a member of the EBNER Group since 2010. This year, Gautschi will celebrate its 100th anniversary with a technical seminar and customer event in September. During this event, the Castwork Revolu-tion Center will be opened. The center was launched in 2020 during the COVID-19 pandemic. This will be a great opportunity to get a close look at the center and its capabilities.

I look forward to welcoming our customers and partners. You are welcome to attend this celebration.

Sincerely,

Robert EBNER

CEO of the EBNER Group

(+86) 512/5320 8896

(+86) 512/5320 8896 CN

CN

2020.06.15

2020.06.15